In industries ranging from manufacturing to robotics, the ongoing drive toward efficiency, precision, and sustainability has spurred the transition from traditional fluid-based technologies to advanced servo motor systems. As automation becomes more integral to modern production lines, the shift to servo motors offers compelling advantages across multiple aspects of operations.

Here’s a closer look at why businesses are increasingly opting to replace fluid-based technologies with servo motor solutions:

1. Enhanced Precision and Control

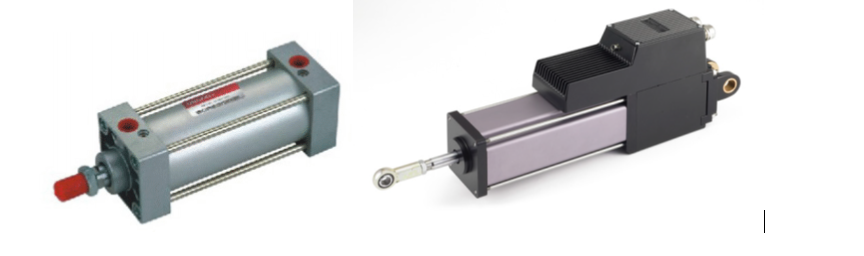

One of the most significant benefits of servo motor technology is the precision it offers. Unlike fluid power systems that rely on hydraulic or pneumatic pressures to control movements, servo motors use electrical signals for precise control over speed, torque, and position. This high degree of accuracy is essential in industries like automotive manufacturing, aerospace, and medical devices, where even the smallest variation can lead to product defects or system failures.

With servo motors, manufacturers can easily adjust and fine-tune movements in real-time, ensuring that each cycle is consistent and accurate. This level of control is difficult, if not impossible, to achieve with fluid-based systems, where variations in pressure or temperature can cause fluctuations in performance.

2. Reduced Maintenance and Operational Costs

Fluid-based systems, particularly hydraulic and pneumatic solutions, require regular maintenance to ensure smooth operation. Leaks, contamination, and wear and tear on seals and components are common issues that can lead to costly downtime. Moreover, hydraulic fluid often needs to be replaced and disposed of, which can be both expensive and environmentally hazardous.

On the other hand, servo motors are solid-state electrical components that typically require far less maintenance. They have fewer moving parts, and their reliability is much higher compared to fluid-based systems. The absence of fluid also eliminates the risks associated with leaks and contamination. The long lifespan and low maintenance requirements of servo motors help businesses save on operational costs over time.

3. Increased Energy Efficiency

Energy efficiency is a critical consideration for companies looking to reduce operational costs and meet sustainability goals. Fluid-based systems, especially hydraulic systems, often waste energy through heat dissipation and pressure losses. In contrast, servo motors are much more energy-efficient.

Servo systems adjust their energy consumption based on the specific needs of the operation, drawing only the required amount of energy. This variable-speed operation is far more efficient than fluid systems, which typically require a constant supply of energy to maintain pressure levels, even when full power isn’t necessary.

Additionally, the energy consumed by servo motors is directly related to the workload they are performing, offering a level of efficiency that fluid systems cannot match. This helps companies reduce their energy bills while minimizing their carbon footprint.

4. Improved Response Times and Speed

Servo motors excel in applications that require high-speed, dynamic movement. Fluid-based systems are inherently slower, as they rely on the compression and release of air or the movement of liquid to generate force. This process takes time, especially when fine-tuning is required.

In contrast, servo motors can achieve rapid, precise movements almost instantaneously. This increased speed is especially beneficial in industries where time-to-market is critical. Whether it’s for robotics, packaging, or CNC machining, the ability to make faster adjustments means companies can achieve higher throughput and productivity, ultimately reducing lead times and improving competitiveness.

5. Compact and Versatile Design

Another key advantage of servo motors over fluid-based systems is their compact size. Hydraulic and pneumatic systems often require bulky pumps, hoses, valves, and reservoirs, which take up a significant amount of space. These systems can be cumbersome and difficult to integrate into smaller or more space-constrained environments.

Servo motors, by comparison, are more compact and can be easily integrated into a wide variety of machine designs. They also offer greater flexibility, enabling manufacturers to design more complex, compact systems without sacrificing performance. This versatility can lead to innovations in product design and more efficient use of available space.

6. Environmentally Friendly

Fluid-based systems, particularly those using hydraulic oil, can present environmental risks if there are leaks or spills. The disposal of used fluids also poses a challenge, as they can contain harmful chemicals that need to be carefully managed.

In contrast, servo motors are typically free of hazardous fluids, making them a more environmentally friendly option. Not only does this reduce the risk of environmental damage, but it also simplifies the regulatory compliance process for businesses, as they do not have to deal with the environmental impacts of fluid disposal and contamination.

7. Enhanced System Integration

The integration of servo motors with other automation technologies is generally easier than integrating fluid-based systems. Servo motors are often part of sophisticated control systems that allow for seamless communication with other components, such as sensors, controllers, and PLCs (Programmable Logic Controllers). This integration enables advanced functionalities, such as predictive maintenance, real-time monitoring, and automatic adjustments based on performance data.

Fluid-based systems, on the other hand, often require specialized equipment and maintenance procedures that make system integration more complex and costly. Moreover, the flexibility and adaptability of servo motors make them ideal for modern, smart manufacturing environments, where interconnected systems work together to optimize production.

8. Better Safety Features

Safety is always a priority in industrial operations, and fluid-based systems can present significant risks. Hydraulic systems, for instance, can generate high pressures that pose a danger if the system fails. There are also risks associated with handling, storing, and disposing of hydraulic fluids.

Servo motors, in comparison, are much safer to operate. While they do carry electrical risks, they generally pose fewer hazards in day-to-day operations. Additionally, the precise control offered by servo motors reduces the likelihood of accidents caused by overshooting or overcompensating movements, a common issue in fluid-based systems.

Servo system also integrate technology like STO ( safe Torque Off ) and some system also include safe speed monitoring or safe position. Those function in fluid power required additional component like safety redundant valve and safety sensors to achieve the same function, making the integration much simpler and less expensive with servo based systems.

Conclusion

The transition from fluid-based technology to servo motor systems is not merely a trend—it represents a fundamental shift toward more efficient, precise, and sustainable automation solutions. Servo motors offer substantial advantages in terms of precision, energy efficiency, maintenance, speed, and safety, making them a clear choice for industries aiming to stay competitive in an increasingly automated world.

While fluid-based systems still have a place in certain applications, the growing demand for high-performance, low-maintenance, and environmentally friendly technologies makes servo motors a more attractive option for modern industrial needs.

Prosynergic offer free consultation service to help you select the right servo technology for your application.

Contact Us for an appointment info@prosynergic.com