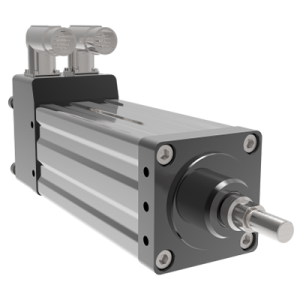

LinMot offers a new drives in the popular C1200 servo drive range.

The C1250-Mi for Multi-Interface

The advantage of this series and its flexibility. The same unit can be configured for the following networks: Profinet/Profidrive, Ethernet IP/CIP Sync, Lin UPP, Powerlink, Sercos III, Ethercat/CiA402, CC-link. So less inventory and more availability.

We encourage you to upgrade to the 1250-MI version for your linear motor from LinMot for your future Project

In addition a version with STO functionality (Safe torque off) is available to simplify your projects that require security.

Contact us for more details