Category: Actuator

We have the accessories you need for your robotic projects!

We have the accessories you need

Murrplastik Robots and Cable Chains

Guide Rail, Schneeberger Rack

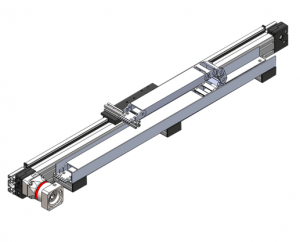

Guided Macron Dynamic Belt Actuator

Hokuyo Safety Laser Scanner

ASO Safety mat and safety bumper

Anubis 3d Robots Tools

Linmot Linear Motor for Adjustable Motorized Tools

Linear Encoder, Safety encoder, Sensors and Vison Tr Electronic Sensor

For more information

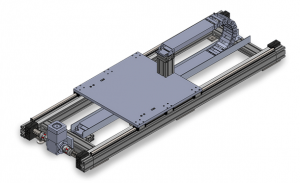

New Macron Dynamic solutions for transporting Robots 7 and 8th axis

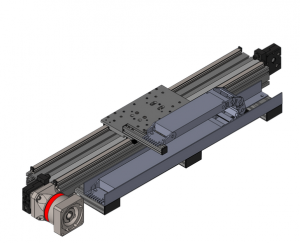

The whole family solution for 7th axis of Macron Dynamics

A nice way to get your project on a fast track !

Robot Mount Plate, Gear Reducer Machine Ready for Your Motor , Wiring Management, Proven Design, You only have to plug your control component and start programming.

Possibility of combination of 7 and 8 axes with a counterweight to compensate the weight of the robot , allowing a smaller motor and a safer application. The weight is integrated in the aluminum structure.

Contact us for more detail or a quick quote

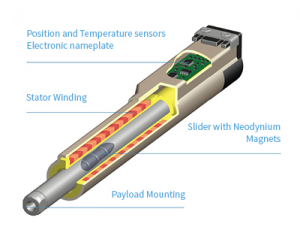

Prosynergic is now the agent for Linmot in Quebec

Prosynergic is the proud representative since January 2020 of NTI AG’s products in Quebec. They manufacture Linmot-branded linear cylindrical motors and Magspring springs. You have to see them as linear servos motors. The product is innovative and highly efficient, with accelerations as high as 7.3G and IP69K versions. They are ideal for the food industry or high production rates and high pressure washing are common. Linmot products replace pneumatic cylinders, in addition to giving you a complete control of speed and positioning, they are more energy efficient. As pneumatic energy is one of the most expensive to produce and transmit to equipment. They are also easy to apply thanks to their format and weather protection.

Linmot headquarters

Contact us to learn how to improve your machine’s performance by replacing your electric or pneumatic cylinders with linear servo technology.

What do you need to know to choose an Actuators or Linear Robots?

What questions to ask when choosing an actuator or linear robots to avoid selection errors

What Precision I’m looking for (Precision and repeatability), this will help us choose which family and type of product we will have to choose the solution in, and the need to have a linear coder and a closed loop on the actual position of the system.

What orientation will the system be installed? Vertical, horizontal, angled, The forces applied to the cart will be different and the gravitational force will have to be taken into account.

What speed , and acceleration the system have to support ? The engine capacity, Drive and, support, bearing will have to withstand the forces of acceleration and deceleration of the system and be able to deliver the required performance

What Length ? Including acceleration and deceleration zone to achieve required speed

What’s the Load ? The weight and its distribution as well as the forces applied with their directions. Any loads deported from the rolling system will result in a moment of force, which the system must be able to withstand without introducing a position error. Any workload performed by the actuator, (cut, push, pull, polish) , Include the weight of the tool, servo motor, gearbox and other axes.

What is the work cycle, and durability required by the application

Other factors to consider, safety, brake for the load, other forces, motor manufacturer and model

What type of environment the product will be subjected to, temperature, debris, chemical, wash down , type of maintenance. Influences the selection of materials and type of bearing and lubrication required.

Hoping that this list of questions helps you better visualize your needs, You can contact Prosynergic to discuss your application it will be our pleasure to help you.

Prosynergic is now the agent for Schneeberger linear technology

![]()

Prosynergic is now the agent for Schneeberger Linear Technology, a manufacturer of linear guidance solution. Founded in 1923 Schneeburger have developed several innovative technologies. In 1945 they created linear technology without friction and a few years ago they integrated a position measurement technology with linear guide rail. It creates the AMS, a guidance system with linear ruler in a single piece. They also offer Mineral casting , that give your the performance of Granite at a fraction of the cost. Also available from Schneeberger ,are high precision table and complete positioning systems

For more details contact us or visit the Schneeburger website

New Delta robots at Macro Dynamics the Tri-Bot

Macron Dynamic now offers a Delta robot named the Tri-bot

Designed from proven linear components Macron now offers a high speed option to the packaging industry

With his modular design it is possible to build custom unit on a large scale

The standard version is capable of 132 Pic per minute and a precision more or plus or minus ten thousandths of an inche

Contact Prosynergic for more details

Info@prosynergic.com

Macron and Prosynergic will be present at ATX Montreal

Thank’s for attending !

Visit us at the ADM Montreal exhibit at Booth 1216

This year the exhibition combines several

Macron Dynamic is a manufacturer of linear motion Cartesian systems and solutions. Macron products are manufactured with the highest quality materials assembled in North America and designed to withstand high-cycle applications. The result is a combination of versatility, durability and virtually maintenance-free operation.

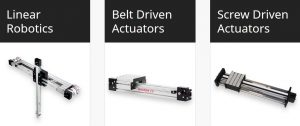

Linear Robotic, Gantry, Linear Belt Actuator, Stainless Actuator, Rod Actuator, Custom Solution , TBot, Hbot

https://www.macrondynamics.com/

Show web site :

See you there !

Macron Dynamic

Cartesian robots – systems gantry – positioning table – linear actuator

- Macron Dynamics Solution for

- Pick & Place

- Sorting, palletizing

- Order management

- Automation

Positioning solutions since 1987

Business context

Based in Philadelphia, Pennsylvania, today, Macron manufactures products of linear Robotics and automation systems designed to help clients to improve productivity and reduce costs through innovative components of movement and high quality.

Defence and aerospace, manufacturing and packaging, medical and pharmaceutical products, film production and theater, the Macron products are used in applications requiring automation of quality… regardless of the market.

Solutions of automation for today’s challenges

Solution of palletizer:

Custom Actuator for outside use, maintenance free