Category: Robotics

LinMot Rotary and Linear Motors, An interesting way to simplify your designs.

PR02

LinMot manufactures servo actuators that combine Linear and Rotary motions in a single assembly. Two large families are available the PR01 and the PR02. The Pr01 is thinner and longer and this is characterized by a set of two motors, one behind the other.it offers versions with reducers for applications that require more rotary torque in addition to a compact mount in width For the PR02 series the two motors are installed in parallel in a single aluminum case. Ideal design for the pharma, cosmetic and beverage industry. In addition in the PR02 version, force sensors and integrated magnetic springs are available for caper or other applications requiring precise monitoring of the applied force and cancellation of the gravitational force. Just like other LinMot products, the high performance of the product will took your breath away as evidenced by the attached videos. If you are a designer who likes to think outside the box, you want to integrate 4.0 technology into your machines LinMot Linear and Rotary Motor will save you time and space in your machines and will set you apart from the competition.

Contact Prosynergic to discuss application and begin the transition of your production technology to the future 😉

New Version PR02 Features and Benefits

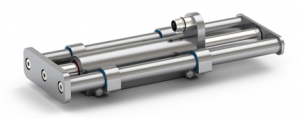

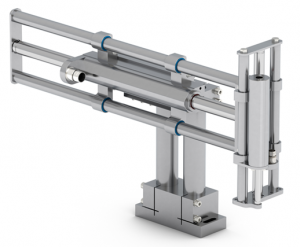

New! IP69K stainless steel actuator at Linmot

LinMot introduces new stainless steel actuators. The new generation features a new, more compact design that improves heat dissipation. The new approach increases the power, decreases the mass of the units and eliminates the use of liquid cooling. The new Linear Motors is an addition to the current range to make one of the best IP69K offerings on the market 😎

In addition a Guided version is available, with more rigidity than the original version thanks to the larger guide. The shaft are hollow so the weight and inertia remains low.

It is also possible to combine the units to produce a complete Pick and Place solution ideal for applications with wash down

(Meat, Chicken, Dairy Products, Pharmaceuticals)

Please contact us for a presentation on new Linmot products or a quotation

A virtual tour of Linmot USA’s demo room

Hello we offer you a guided tour of the demo room of Limot Usa

A great way to see the different products in action

Including the new linear and rotating PR02 Motor with force sensor and smooth housing

Have a good visit !

If you need information about any of these products contact us

We have the accessories you need for your robotic projects!

We have the accessories you need

Murrplastik Robots and Cable Chains

Guide Rail, Schneeberger Rack

Guided Macron Dynamic Belt Actuator

Hokuyo Safety Laser Scanner

ASO Safety mat and safety bumper

Anubis 3d Robots Tools

Linmot Linear Motor for Adjustable Motorized Tools

Linear Encoder, Safety encoder, Sensors and Vison Tr Electronic Sensor

For more information

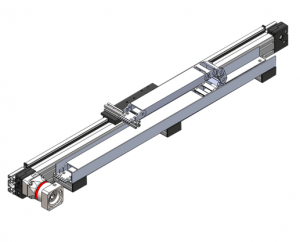

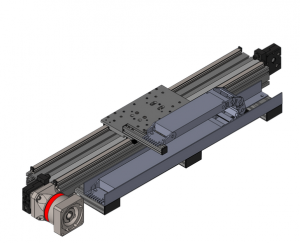

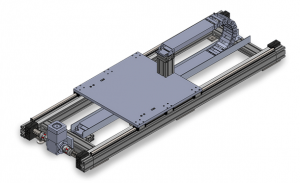

New Macron Dynamic solutions for transporting Robots 7 and 8th axis

The whole family solution for 7th axis of Macron Dynamics

A nice way to get your project on a fast track !

Robot Mount Plate, Gear Reducer Machine Ready for Your Motor , Wiring Management, Proven Design, You only have to plug your control component and start programming.

Possibility of combination of 7 and 8 axes with a counterweight to compensate the weight of the robot , allowing a smaller motor and a safer application. The weight is integrated in the aluminum structure.

Contact us for more detail or a quick quote

What do you need to know to choose an Actuators or Linear Robots?

What questions to ask when choosing an actuator or linear robots to avoid selection errors

What Precision I’m looking for (Precision and repeatability), this will help us choose which family and type of product we will have to choose the solution in, and the need to have a linear coder and a closed loop on the actual position of the system.

What orientation will the system be installed? Vertical, horizontal, angled, The forces applied to the cart will be different and the gravitational force will have to be taken into account.

What speed , and acceleration the system have to support ? The engine capacity, Drive and, support, bearing will have to withstand the forces of acceleration and deceleration of the system and be able to deliver the required performance

What Length ? Including acceleration and deceleration zone to achieve required speed

What’s the Load ? The weight and its distribution as well as the forces applied with their directions. Any loads deported from the rolling system will result in a moment of force, which the system must be able to withstand without introducing a position error. Any workload performed by the actuator, (cut, push, pull, polish) , Include the weight of the tool, servo motor, gearbox and other axes.

What is the work cycle, and durability required by the application

Other factors to consider, safety, brake for the load, other forces, motor manufacturer and model

What type of environment the product will be subjected to, temperature, debris, chemical, wash down , type of maintenance. Influences the selection of materials and type of bearing and lubrication required.

Hoping that this list of questions helps you better visualize your needs, You can contact Prosynergic to discuss your application it will be our pleasure to help you.

New products, lightweight EOAT for Robots from Anibus 3D

Prosynergic now represents the products of Anubis 3D. This Canadian manufacturer uses a new SLS-type 3D printing technology that allows the production of volume parts. Unlike other printing process the parts are ultra-precise, and their properties do not change in time. The final product is robust and can be used as a production part. The result is more competitive and flexible than the injection processes for low and medium volume parts.

Anubis 3D has therefore specialised in the manufacture of robots tools because the properties of the final products are ideal for the industry. The robots tools must be robust, lightweight and flexible, all of which are the qualities that make it. Thanks to the next generation computer aided design using artificial intelligence, the tools are developed by our teams of engineers according to the customer’s need and are manufactured in a few days. The built-in tool include air conduit and the shape is optimised for any force applied.

Anubis 3D has several projects that have been saved by our technology. The large weight of conventional tools tax the robots that are struggling to reach the required production rate. In several applications the tool is heavier than the load to be moved. The Anubis 3D technology is collaborative robot friendly. This type of robots less powerful than conventional robots will be well served by the low-weight tools Anubis 3D produce.

Please contac Us for a free quote

New Delta robots at Macro Dynamics the Tri-Bot

Macron Dynamic now offers a Delta robot named the Tri-bot

Designed from proven linear components Macron now offers a high speed option to the packaging industry

With his modular design it is possible to build custom unit on a large scale

The standard version is capable of 132 Pic per minute and a precision more or plus or minus ten thousandths of an inche

Contact Prosynergic for more details

Info@prosynergic.com

Macron and Prosynergic will be present at ATX Montreal

Thank’s for attending !

Visit us at the ADM Montreal exhibit at Booth 1216

This year the exhibition combines several

Macron Dynamic is a manufacturer of linear motion Cartesian systems and solutions. Macron products are manufactured with the highest quality materials assembled in North America and designed to withstand high-cycle applications. The result is a combination of versatility, durability and virtually maintenance-free operation.

Linear Robotic, Gantry, Linear Belt Actuator, Stainless Actuator, Rod Actuator, Custom Solution , TBot, Hbot

https://www.macrondynamics.com/

Show web site :

See you there !