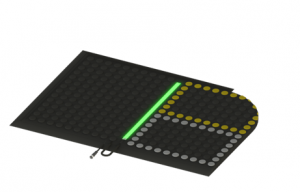

Your process or environment is dusty or your environment is difficult, you can’t afford a costly production down time .ASO safety offers safety sensing products that use pressure to sence a presence. The product is available in three forms. The first form, as a safety mat , it detects the presence with the weight that compresses two steel plates which disables the safety functions. The mats are made with two steel plates, separated from insulators, they are sturdy and are available with an additional covering of stainless steel or aluminum. And the second, in the form of palpous bar, which under the pressure of an object or a part of the body deforms to activate two conductive areas together and detected their deflection. Ideal for protecting crushing areas . And the third, in the form of a safety bumber, having the function of absorbing a shock in addition to sensing the presence of an impact at the front of an AGV (Auto-Guide vehicle).

Contact us for prices or advice for product selection

info@prosynergic.com