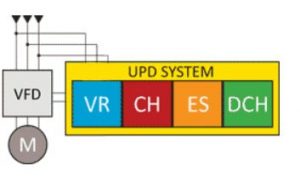

Do you have critical applications that can’t be interrupted or voltage variations that cause your drive to trip ? For example, the time it takes for the generator to switch from the Hydro voltage to the generator may be long enough to trigger a fault on your drive or your plant is at the end of the line and the voltage fluctuates and trip the drive.Bonitron is a name to remember in those situation they manufactures multiple solution. They have units called UPD. Like a Ups these units take over during power outage but provide only DC energy. The AC Drive have already a power converter so it is not necessary and much more efficient to not do the conversion 2 time . The result is a more reliable and more price effective solution than a UPS. Also as the solution is parallel it does not prevent your Drive from working if the UPS has issue.

If your voltage interruptions are short. There is also a solution based on capacitors that will be plugged in parallel to the DC Bus of your Drive. This additional capacity allows energy to be stored to overcome the problems of voltage variation.

Your Drive can also trip on over voltage, which is normally due to regeneration of your motor when it is being tracked by the load. The generator effect of your motor inflates your DC bus and the drive trip to protect itself. It is then necessary to precede to deflate the DC bus by consuming the excess energy. Option 1, use resistance to burn energy or Option 2 returns this surplus on the power line. The greener solution is regeneration, because the energy is not wasted in heat but rather returned so that other load can consume it. There are accessories on the market to create a common DC Bus with multiple drive , this way an accelerating drive can consume the current of another drive in deceleration. This common bus solution will reduce the size of the regeneration unit in addition to limited to one unit per group of drive . The beauty of the solution , it can be done with regular of the shelf drive , all you need is a connection to the DC bus of the drive.

Another interesting option is for cycle loads, which go from motor to generator state constantly. Like an oil pump jack. When the pump goes up it consumes power when it comes down it regenerates. Capacitors can then be installed to store during the descent and provide energy to the climb.

For more solution please contact Us

We can help fix issue with all drive brand

Gilles Laberge

Prosynergic

Info@prosynergic.com