You want to built your own project , we can help you

You can even get the beam has a component

Contact Us for a Quote

You want to built your own project , we can help you

You can even get the beam has a component

Contact Us for a Quote

In industries ranging from manufacturing to robotics, the ongoing drive toward efficiency, precision, and sustainability has spurred the transition from traditional fluid-based technologies to advanced servo motor systems. As automation becomes more integral to modern production lines, the shift to servo motors offers compelling advantages across multiple aspects of operations.

Here’s a closer look at why businesses are increasingly opting to replace fluid-based technologies with servo motor solutions:

1. Enhanced Precision and Control

One of the most significant benefits of servo motor technology is the precision it offers. Unlike fluid power systems that rely on hydraulic or pneumatic pressures to control movements, servo motors use electrical signals for precise control over speed, torque, and position. This high degree of accuracy is essential in industries like automotive manufacturing, aerospace, and medical devices, where even the smallest variation can lead to product defects or system failures.

With servo motors, manufacturers can easily adjust and fine-tune movements in real-time, ensuring that each cycle is consistent and accurate. This level of control is difficult, if not impossible, to achieve with fluid-based systems, where variations in pressure or temperature can cause fluctuations in performance.

2. Reduced Maintenance and Operational Costs

Fluid-based systems, particularly hydraulic and pneumatic solutions, require regular maintenance to ensure smooth operation. Leaks, contamination, and wear and tear on seals and components are common issues that can lead to costly downtime. Moreover, hydraulic fluid often needs to be replaced and disposed of, which can be both expensive and environmentally hazardous.

On the other hand, servo motors are solid-state electrical components that typically require far less maintenance. They have fewer moving parts, and their reliability is much higher compared to fluid-based systems. The absence of fluid also eliminates the risks associated with leaks and contamination. The long lifespan and low maintenance requirements of servo motors help businesses save on operational costs over time.

3. Increased Energy Efficiency

Energy efficiency is a critical consideration for companies looking to reduce operational costs and meet sustainability goals. Fluid-based systems, especially hydraulic systems, often waste energy through heat dissipation and pressure losses. In contrast, servo motors are much more energy-efficient.

Servo systems adjust their energy consumption based on the specific needs of the operation, drawing only the required amount of energy. This variable-speed operation is far more efficient than fluid systems, which typically require a constant supply of energy to maintain pressure levels, even when full power isn’t necessary.

Additionally, the energy consumed by servo motors is directly related to the workload they are performing, offering a level of efficiency that fluid systems cannot match. This helps companies reduce their energy bills while minimizing their carbon footprint.

4. Improved Response Times and Speed

Servo motors excel in applications that require high-speed, dynamic movement. Fluid-based systems are inherently slower, as they rely on the compression and release of air or the movement of liquid to generate force. This process takes time, especially when fine-tuning is required.

In contrast, servo motors can achieve rapid, precise movements almost instantaneously. This increased speed is especially beneficial in industries where time-to-market is critical. Whether it’s for robotics, packaging, or CNC machining, the ability to make faster adjustments means companies can achieve higher throughput and productivity, ultimately reducing lead times and improving competitiveness.

5. Compact and Versatile Design

Another key advantage of servo motors over fluid-based systems is their compact size. Hydraulic and pneumatic systems often require bulky pumps, hoses, valves, and reservoirs, which take up a significant amount of space. These systems can be cumbersome and difficult to integrate into smaller or more space-constrained environments.

Servo motors, by comparison, are more compact and can be easily integrated into a wide variety of machine designs. They also offer greater flexibility, enabling manufacturers to design more complex, compact systems without sacrificing performance. This versatility can lead to innovations in product design and more efficient use of available space.

6. Environmentally Friendly

Fluid-based systems, particularly those using hydraulic oil, can present environmental risks if there are leaks or spills. The disposal of used fluids also poses a challenge, as they can contain harmful chemicals that need to be carefully managed.

In contrast, servo motors are typically free of hazardous fluids, making them a more environmentally friendly option. Not only does this reduce the risk of environmental damage, but it also simplifies the regulatory compliance process for businesses, as they do not have to deal with the environmental impacts of fluid disposal and contamination.

7. Enhanced System Integration

The integration of servo motors with other automation technologies is generally easier than integrating fluid-based systems. Servo motors are often part of sophisticated control systems that allow for seamless communication with other components, such as sensors, controllers, and PLCs (Programmable Logic Controllers). This integration enables advanced functionalities, such as predictive maintenance, real-time monitoring, and automatic adjustments based on performance data.

Fluid-based systems, on the other hand, often require specialized equipment and maintenance procedures that make system integration more complex and costly. Moreover, the flexibility and adaptability of servo motors make them ideal for modern, smart manufacturing environments, where interconnected systems work together to optimize production.

8. Better Safety Features

Safety is always a priority in industrial operations, and fluid-based systems can present significant risks. Hydraulic systems, for instance, can generate high pressures that pose a danger if the system fails. There are also risks associated with handling, storing, and disposing of hydraulic fluids.

Servo motors, in comparison, are much safer to operate. While they do carry electrical risks, they generally pose fewer hazards in day-to-day operations. Additionally, the precise control offered by servo motors reduces the likelihood of accidents caused by overshooting or overcompensating movements, a common issue in fluid-based systems.

Servo system also integrate technology like STO ( safe Torque Off ) and some system also include safe speed monitoring or safe position. Those function in fluid power required additional component like safety redundant valve and safety sensors to achieve the same function, making the integration much simpler and less expensive with servo based systems.

Conclusion

The transition from fluid-based technology to servo motor systems is not merely a trend—it represents a fundamental shift toward more efficient, precise, and sustainable automation solutions. Servo motors offer substantial advantages in terms of precision, energy efficiency, maintenance, speed, and safety, making them a clear choice for industries aiming to stay competitive in an increasingly automated world.

While fluid-based systems still have a place in certain applications, the growing demand for high-performance, low-maintenance, and environmentally friendly technologies makes servo motors a more attractive option for modern industrial needs.

Prosynergic offer free consultation service to help you select the right servo technology for your application.

Contact Us for an appointment info@prosynergic.com

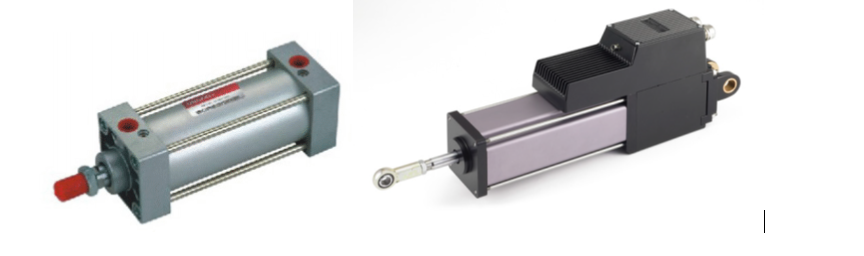

We are proud to represent Gudel for Ontario, Quebec and the Atlantic province

Gudel has been a market leader in Automation since 1954 . from high-precision machine components to intelligent automation solutions offer innovative solutions.

The technology of Güdel is characterized by its innovation, modularity and quality. Güdel has around 1000 employees in over 20 locations around the world.

Prosynergic will represent the automation division as well as the component division.

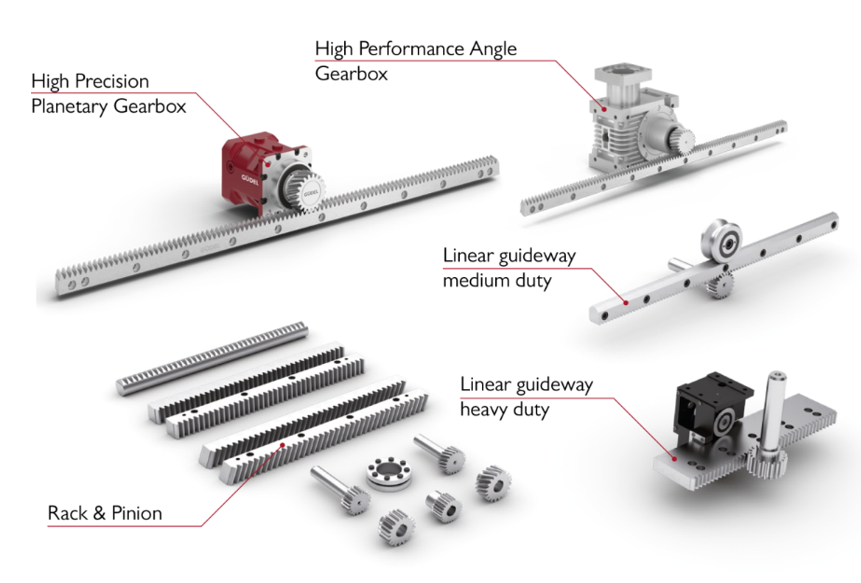

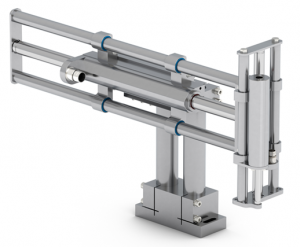

Gudel offers X-Y-Z heavy robots, gantries. robots track and their component. They have Gearbox, Gear Rack, and linear guide ways.

They also sell the system in modular kit to reduce cost and ease of ordering

You have something heavy to move, Gudel has the solution and the industry expertise to help you.

Special Area of Expertise

Press Automation, Robot Feeder, Blank Destacking , End of Line

Tire Handling, Logistic, Composite manufacturing, Railway handling , Glass Handling

Powertrain Handling, Battery Handling, Sorting, Palletizing

LinMot offers a new drives in the popular C1200 servo drive range.

The C1250-Mi for Multi-Interface

The advantage of this series and its flexibility. The same unit can be configured for the following networks: Profinet/Profidrive, Ethernet IP/CIP Sync, Lin UPP, Powerlink, Sercos III, Ethercat/CiA402, CC-link. So less inventory and more availability.

We encourage you to upgrade to the 1250-MI version for your linear motor from LinMot for your future Project

In addition a version with STO functionality (Safe torque off) is available to simplify your projects that require security.

Contact us for more details

We are proud to be able to offer to our Quebec customers Exlar® brand products, a product manufactured by curtiss-Wright

![]()

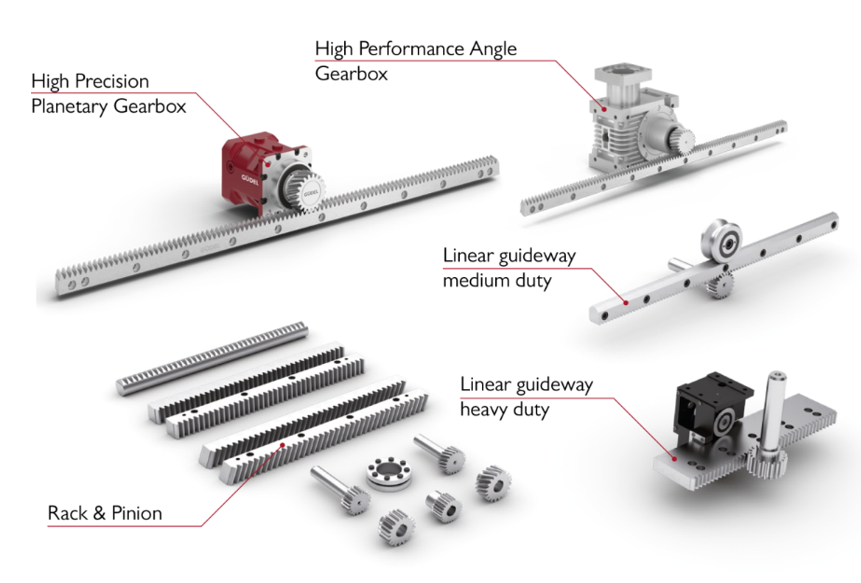

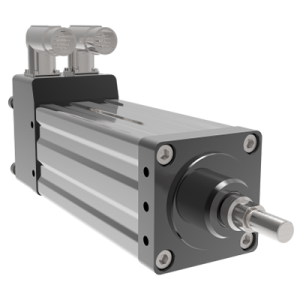

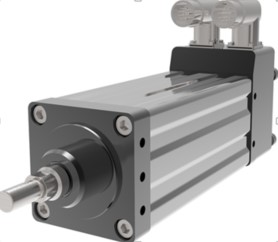

The industrial division of Curtiss-Wright designs and manufactures Exlar® electric screw and roller actuators, rotary servo motors and integrated actuator solutions for a wide range of applications. The unique linear roller screw actuator technology provides efficient electromechanical replacement for hydraulic or pneumatic cylinders with forces of up to 80,000 pounds and speeds of up to 60 inches per second. They are able to provide higher force in a smaller package than other actuator technologies, as well as greater flexibility, greater efficiency and reduced maintenance compared to traditional hydraulic and pneumatic solutions.

GSX actuator with integrated servo motor

Contact us for more details

PR02

LinMot manufactures servo actuators that combine Linear and Rotary motions in a single assembly. Two large families are available the PR01 and the PR02. The Pr01 is thinner and longer and this is characterized by a set of two motors, one behind the other.it offers versions with reducers for applications that require more rotary torque in addition to a compact mount in width For the PR02 series the two motors are installed in parallel in a single aluminum case. Ideal design for the pharma, cosmetic and beverage industry. In addition in the PR02 version, force sensors and integrated magnetic springs are available for caper or other applications requiring precise monitoring of the applied force and cancellation of the gravitational force. Just like other LinMot products, the high performance of the product will took your breath away as evidenced by the attached videos. If you are a designer who likes to think outside the box, you want to integrate 4.0 technology into your machines LinMot Linear and Rotary Motor will save you time and space in your machines and will set you apart from the competition.

Contact Prosynergic to discuss application and begin the transition of your production technology to the future 😉

New Version PR02 Features and Benefits

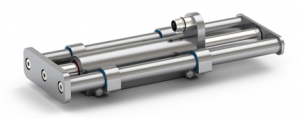

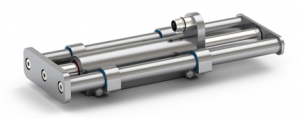

It is quite possible to reconcile, two things that seemed opposite not so long ago, thanks to the new technology. Reduce energy consumption and increase the performance of a machine. Pneumatic technologies for example are very inefficient, in some cases there is only 10% of the energy consumed that is used by the cylinders the rest is lost in heat and other losses in the system. In addition to generating more noise they require a compressor, an imposing amount of air preparation device (lubricator, regulator, accumulator, valve and silencer). The maintenance of these devices is intensive and in some cases the adjustment of the regulators is more witchcraft than technique. A change in temperature or humidity can result in a complete adjustment. Not to mention the replacement of the cylinders because the cousin at the end of the stroke no longer does its job or that the operator has changed the pressure of the system. LinMot has developed a linear motor that has the shape of a cylinder but the properties of a servo motor.

Stainless steel Servo Motor Guided LinMot

So complete control over speed and position. In addition, the technology does not include wear parts and requires very little maintenance. You will be able to increase the pace without breaking the equipment, in addition to an increase of efficiency ( 95% to 98%) , the solution is also not influenced by moisture. Once adjusted the actions will be repetitive and will not change over time. This results in a reduction in startup time and reduction of service calls on the machine.

Another technology that consumes quite a lot of energy is hydraulics. The efficiency of this technology is about 50% and also uses several more or less complex devices to make everything work 🙁 Pump, Regulator, Piping, Cooler, Valve and Oil Tank). Oil is increasingly becoming an environmental concern especially in food processes. There are vegetable oils but it is less durable and requires more maintenance. Oil changes generate waste that can be potentially mismanaged

There are linear positioning technologies in the form of cylinder, belt or rack and pinion that are powered by a Servo motor that have an efficiency of more than 90%.

Their accuracy is better and so is their durability. For the most part maintenance-free other than lubrication of their bearings they present less risk to the environment and are much greener and more efficient technologies.

Another source to improve your energy efficiency is to favour high-efficiency speed reducers. Worm Gear type gearboxes generally have a low efficiency VS Planetary or helical gearbox. So pay attention to the choices of your gearboxes and try to choose products in the 90% efficiency. There is up to 40% energy saving possible. Especially in large gear ratio .

There also other benefit with lower friction comes lower heat dispassion , so your gearbox run cooler and you will need less BTU to cool down your plant. Your Oil and Seals will also last longer.

Here are some reference articles for you

Comparing-the-Cost-of-Pneumatic-to-Electric

Choosing-Electric-over-Hydraulic-Actuation

In summary it is possible to improve productivity and reduce operating costs if you go electric . New technologies are more expensive but if we take into account the total cost of ownership they become more competitive than traditional linear fluid power option.

In addition the servo drive technologies are already ready for Industry 4.0, You will have a more efficient process in addition of having more data on the process.

For example your drive know in all time : Position and Speed

We are available to work with you on your energy saving program or your machine conversion program

Feel free to contact us

LinMot have combined a rotating and linear axis in the same axis making integration easier. The system controls the position, the speed of all axes in addition, of the force. So you can do a quality control directly to the assembly in addition to being able to store the information in a given database. LinMot also makes integration with the PLC easy thanks to the different version of servo drive available on the most common communications buses. For Rockwell users an EThernet IP version and an CIP Sync version are available.

Macron offers several options for environments with high pressure wash. The whole thing is made to meet the IP69K standards

First of all the aluminum actuator can be equipped with the Stainless option or all the accessories are made of stainless steel and where a standard tubular frame is hard-coated anodized.

Macron also offers for extreme environments the MSA-SSB Series such as the photo above, where the whole body is made of stainless steel.

Optional blue food grade guidance wheels are available.

Contact us for your Wash down actuator need , Macron has several configurations available including custom versions

LinMot introduces new stainless steel actuators. The new generation features a new, more compact design that improves heat dissipation. The new approach increases the power, decreases the mass of the units and eliminates the use of liquid cooling. The new Linear Motors is an addition to the current range to make one of the best IP69K offerings on the market 😎

In addition a Guided version is available, with more rigidity than the original version thanks to the larger guide. The shaft are hollow so the weight and inertia remains low.

It is also possible to combine the units to produce a complete Pick and Place solution ideal for applications with wash down

(Meat, Chicken, Dairy Products, Pharmaceuticals)

Please contact us for a presentation on new Linmot products or a quotation