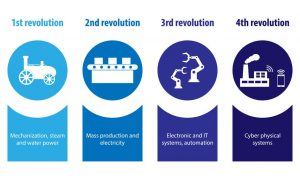

Canada, which is not successful to filled the productivity gap with the other industrialized countries. So we can’t not miss the next turning point of the 4.0 industry. The next industrial Revolution, like any other, will create wealth, winners and losers. I prefer to be a winner and you? Quebec manufacturers who once pulled their game with a low dollar, lower overall costs and a sense of resourcefulness in Quebec will have more and more difficulty in doing so. Several companies did not even take the turn completely 3.0. The well-structured company, equipped with the latest technology will thrive thanks to automation. Their product will be better built. They will have fewer production stops, their customers will know the delivery dates and will be delighted. Do we have a choice? Well no more than Ford’s competitors had, with the chain production.

Ford was doing thing, faster, better cheaper!

The basis of change begins with the simplification of work and the automation of repetitive processes. In the majority of cases the result is a higher rate, more quality, more consistency and more safety for the workers who works with the machines. I think Canada is well positioned. We have invested in our schools and we have a good pool of educated people in addition to having a good basin of aging machinery that needs to be changed. Interest rates are relatively low. We only have to look at the Chinese who currently install more robots than any other country in the world and yet the labor is plentiful and cheap? They may have understood that it is inevitable and strategic.

Now you have to start planning and investing before your company loses its relevance in the market and your low market position makes financing of the new technology impossible. I will not hide that there is a lot of work to arrive at the factory 4.0. But the profits are immense not to mention that the generation of millennial that follows may not want to work in a factory or repetitive work is difficult and stunning or even in a factory where the information is non-existent. This generation is accustomed to finding its info with Google. It will be difficult to understand that nothing is available on your production line. That the reports are made by hand by collecting given data on the right and left. I think they’re right.

So in my humble opinion the turning point is inevitable, if not your industry is doomed, because your competitors will do things better, cheaper and faster than you. Further recruiting new employees to work in outdated factories will be impossible. You don’t want to live the inverted Hygrade phenomenon, fewer people eat it because it is not fresh. Or the inverted spiral that is so scary to Bill Gates.

When buying a car or a new smart phone people want the latest technology, why not do the same thing in our factories. Don’t we spend three quarters of our lives at work?

Need help setting your priorities? Contact us. We have several solutions that are part of the 4.0 industry approach

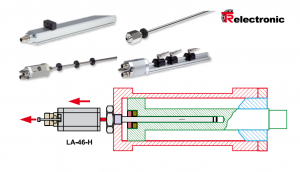

Intelligent sensor, security management, quality control, networking and robotics Infrastructure.

Gilles Laberge

Prosynergic

![]()